Overview

A leading IPP selected a 150+ MWp monofacial HSAT solar site for a performance assessment due to persistent operational challenges and a 9.9% deviation between budgeted and realized energy yields. The site exhibited fluctuating energy production driven by high irradiance variability, which masked the root causes of underperformance.

Building a representative 3D model of the plant, the Enurgen team:

- Reduced model overestimation by 3X compared to PVsyst

- Quantified curtailment losses totalling ~US$15 million over the plant’s lifetime

- Enabled ongoing performance benchmarking for real-time operational improvements

The Challenge

The full system P50 estimate, as projected by the as-built PVsyst model, was upwards of 350,000 MWh/year in energy production, with a revenue expectation of close to US$40 million/year. However, actual performance consistently fell short, and the source of the deviation was unclear.

The PVsyst model uses a 2D view-factor approach and is limited to hourly resolution outputs. As such, it failed to capture the site’s spatial irradiance variability, leading to inaccurate yield estimates and masking key loss contributors.

Enurgen’s Approach

Enurgen built a high-fidelity model of the system, incorporating:

- Sub-hourly solar resource and meteorological data

- 3-dimensional shading of all array elements

- Cell-to-system modelling

- Representative blocks across the site with localized weather averaging

Enurgen’s irradiance algorithm and IV modelling provided a more accurate representation of energy flow across modules, strings, and arrays — without relying on empirical correction factors.

Key Findings

- 9.9% overestimation by PVsyst that led to a ~US$85 million revenue expectation gap over the plant’s 25-year lifetime

- Enurgen reduced overestimation to ~US$1.01 million/year, a 3X improvement

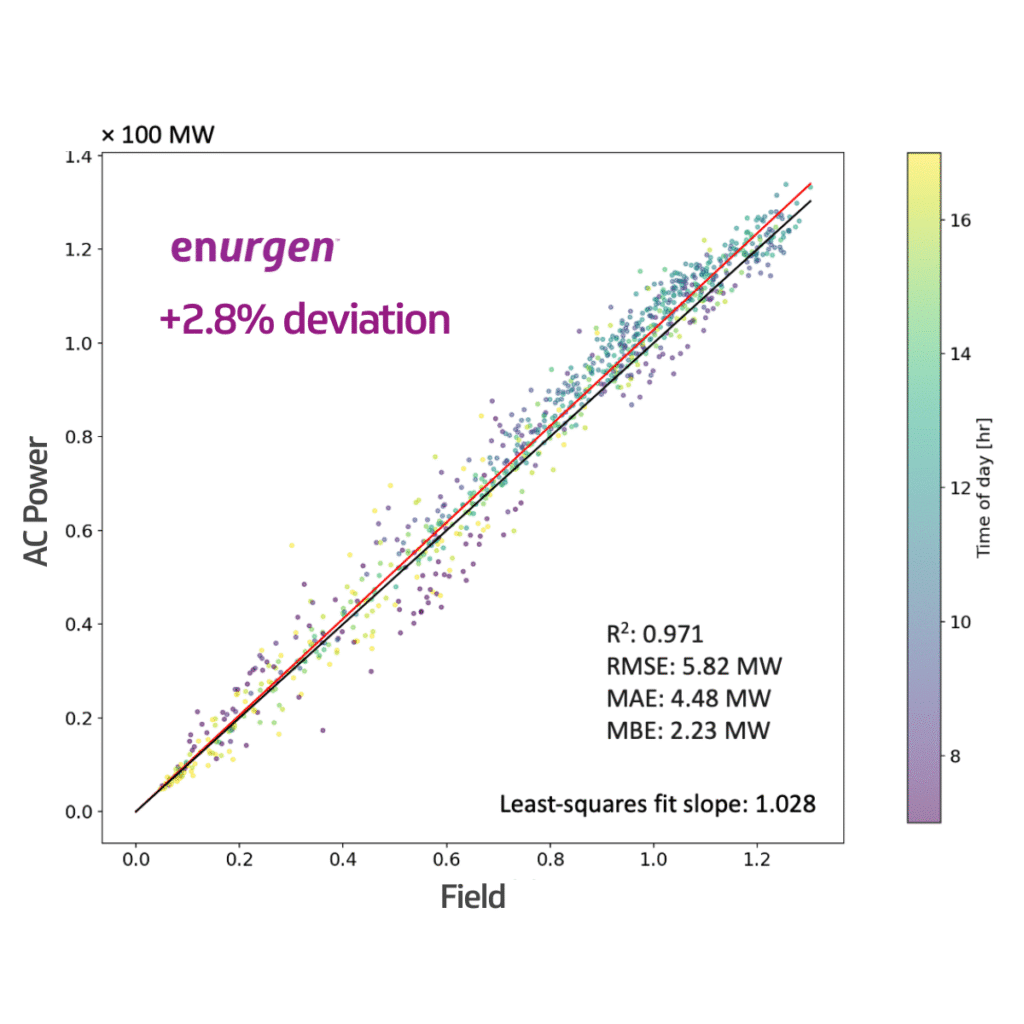

- Remaining 2.8% performance deviation was diagnosed as:

- Irradiance sensor issues

- Plant controller inefficiencies

- Spatial non-uniformity across the array

- Enurgen also enabled curtailment loss quantification, revealing ~US$0.6 million/year in lost revenue —totalling ~US$15 million over the asset’s life

The Outcome

- The IPP is adjusting plant controller strategies to improve inverter efficiency with Enurgen’s guidance and recommendations

- Enurgen’s operational solution has been deployed further across their portfolio to automate performance benchmarking and assessments

Why it Matters

This case highlights the limitations of traditional modelling tools in high-variability environments — and the value of high-resolution, physics-based modelling for operations and performance teams.

Utilizing Enurgen’s 3D finite element method model across the lifecycle of a solar asset—from design, to construction, to operations— enables:

- Faster root-cause analysis

- More accurate yield forecasting

- Actionable insights for O&M and financial planning

- Team alignment and less rework